Stitch Welding

What is Stitch Welding?

Stitch welding, also known as intermittent welding, or skip welding is when you lay multiple welds with spacing between your welds instead of having one long continuous weld running the entire length of the section you are welding.

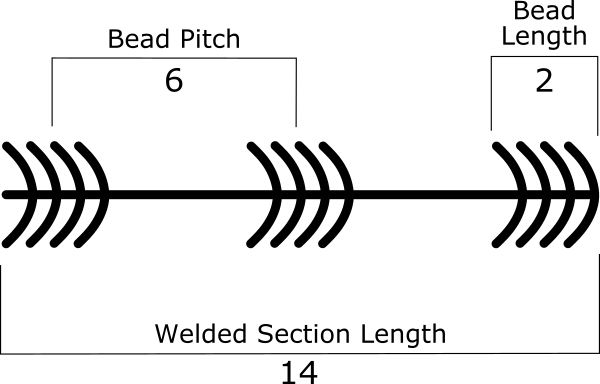

See below for examples of a stitch weld and a continuous weld.

Stitch Weld

- Bead Quantity = 3

- There are three weld beads in this example.

- Bead Length = 2

- Each weld bead is two units long.

- Bead Pitch = 6

- The distance between the center of one weld bead to the next is six units.

- Welded Section Length = 14

- The total welded section length is 14 units from the start of the first weld to the end of the last weld.

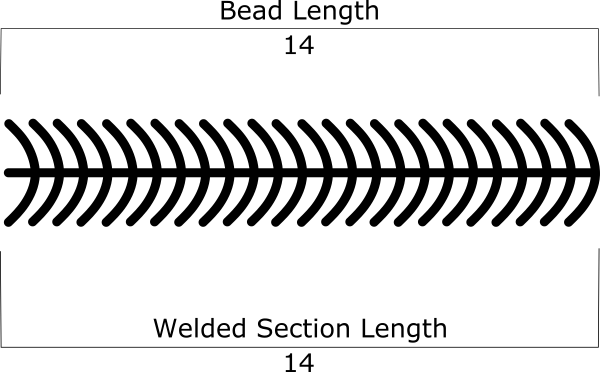

Continuous Weld

- Bead Quantity = 1

- There is only one weld which runs the length of the welded section length.

- Bead Length = Welded Section Length

- The length of the weld is the same as the welded section length because there is only one weld.

- Bead Pitch = N/A

- Bead pitch is the distance between two weld beads. With only one weld bead there is no pitch.

- Welded Section Length = Bead Length

- The welded section length is the total length of the section you are welding from start to finish. In the case of a continuous weld, it is effectively how long your weld bead is.

What is Stitch Welding used for?

Stitch welds are used in many industries including construction, civil engineering and machine manufacturing just to name a few. The main benefits of using stitch welds instead of a continuous weld are to save on material costs and avoid heat distortion. You can find stitch welds both in structural and non-integral assemblies and components.

How do you Stitch Weld?

Before you start, you need to know whether you are welding along a path with two ends, or something circular. The calculation you will use for uniform spacing will be different for each. Our free stitch welding calculator will help you calculate uniform welds. To calculate for circular welds as well, please see our pro tools (Coming Soon!).

Next, you need to determine what you are looking for. There are four parameters that go into the calculator. Bead quantity, bead length, bead pitch and welded section length. You will need to know, or have some idea of three of these four parameters. The calculator will give you the results of the parameter you select.

- Bead Quantity

- Total number of weld beads you are adding to your welded section length.

- Bead Length

- Overall length of one of the weld beads. The calculator assumes they are all equal length.

- Bead Pitch

- Distance from the center of one of your weld beads to the center of the next weld bead. This can also be from the beginning of one weld to the beginning of the next. Note, it is NOT the distance between welds. See our pro version for that information.

- Welded Section Length

- Total length you are welding from where the beginning of your first weld is to the end of your last weld.

Once you have three of the parameters, select the the one you are missing at the top of the calculator to solve for it. Then enter the information you have into the other form fields and click the Calculate button.